Contents

Difference between AI and Robotics

Why is AI Important for Robotics?

How is AI Used in Robotics?

AI Models Powering Robotics Development

Challenges of Integrating AI in Robotics

How Encord Ensures High-Quality Data for Training AI Algorithms for Robotics Applications

Future of Robotics & AI

AI in Robotics: Key Takeaways

Encord Blog

AI and Robotics: How Artificial Intelligence is Transforming Robotic Automation

5 min read

Artificial intelligence (AI) in robotics defines new ways organizations can use machines to optimize operations. According to a McKinsey report, AI-powered automation could boost global productivity by up to 1.4% annually, with sectors like manufacturing, healthcare, and logistics seeing the most significant transformation.

However, integrating AI into robotics requires overcoming challenges related to data limitations and ethical concerns. Also, the lack of diverse datasets for domain-specific environments makes it difficult to train effective AI models for robotic applications.

In this post, we will explore how AI is transforming robotic automation, its applications, challenges, and future potential. We will also see how Encord can help address issues in developing scalable AI-based robotic systems.

Difference between AI and Robotics

Artificial Intelligence (AI) and robotics are different yet interconnected fields within engineering and technology. Robotics focuses on designing and building machines capable of performing physical tasks, while AI enables these machines to perceive, learn, and make intelligent decisions.

AI consists of algorithms that enable machines to analyze data, recognize patterns, and make decisions without explicit programming. It uses techniques like natural language processing (NLP) and computer vision (CV) to allow machines to perform complex tasks.

For instance, AI powers everyday technologies, such as Google's search algorithms, re-ranking systems, and conversational chatbots like Gemini and ChatGPT by OpenAI.

Robotics, however, focuses on designing, building, and operating programmable physical systems that can work independently or with minimal human assistance. These systems use sensors to gather information and may follow programmed instructions to move, pick up objects, or communicate.

The integration of AI with robotic systems helps them perceive their environment, plan actions, and control their physical components to achieve specific objectives, such as navigation, object manipulation, or autonomous decision-making.

Why is AI Important for Robotics?

AI-powered robotic systems can learn from data, recognize patterns, and make intelligent decisions without requiring repetitive programming. Here are some key benefits of using AI in robotics:

Enhanced Autonomy and Decision-Making

Traditional robots use rule-based programs that limit their flexibility and adaptability. AI-driven robots analyze their environment, assess different scenarios, and make real-time decisions without human intervention.

Improved Perception and Interaction

AI improves a robot's ability to perceive and interact with its surroundings. NLP, CV, and sensor fusion enable robots to recognize objects, speech, and human emotions. For example, AI-powered service robots in healthcare can identify patients, understand spoken instructions, and detect emotions through facial expressions and tone of voice.

Learning and Adaptation

AI-based robotic systems can learn from experience using machine learning (ML) and deep learning (DL) technologies. They can analyze real-time data, identify patterns, and refine their actions over time.

Faster Data Processing

The modern robotic system relies on sensors such as cameras, LiDAR, radar, and motion detectors to perceive their surroundings. Processing such diverse data types simultaneously is cumbersome. However, experts can use AI to speed up data processing and enable the robot to make real-time decisions.

Predictive Maintenance

AI improves robotic reliability by detecting wear and tear and predicting potential failures to prevent unexpected breakdowns. This is important in high-demand environments like the manufacturing industry, where downtime can be costly.

How is AI Used in Robotics?

While the discussion above highlights the benefits of AI in robotics, it does not yet clarify how robotic systems use AI algorithms to operate and execute complex tasks. The most common types of AI robots include:

AI-Driven Mobile Robots

An AI-based mobile robot (AMR) navigates environments intelligently, using advanced sensors and algorithms to operate efficiently and safely. It can:

- See and understand its surroundings using sensors like cameras, LiDAR, and radar, combined with CV algorithms to detect objects, recognize obstacles, and interpret their environment.

- Process and analyze data in real time to map out their surroundings, predict potential hazards, and adjust to changes as they move.

- Find the best path and navigate efficiently using AI-driven algorithms to plan routes, avoid obstacles, and move smoothly in dynamic spaces.

- Interact naturally with humans using AI-powered speech recognition, gesture detection, and other intuitive interfaces to collaborate safely and effectively.

AMRs are highly valuable on the factory floor to improve workflow efficiency and productivity. For example, in warehouse inventory management, an AMR can intelligently navigate through aisles, dynamically adjust its route to avoid obstacles and congestion, and autonomously transport goods.

Articulated Robotic Systems

Articulated robotic systems (ARS), or robotic arms, are widely used in industrial settings for tasks like assembly, welding, painting, and material handling. They assist humans with heavy lifting and repetitive work to improve efficiency and safety.

Modern ARS uses AI to process sensor data, enabling real-time perception, decision-making, and precise task execution. AI algorithms help ARS interpret their operating environment, dynamically adjust movements, and optimize performance for specific applications like assembly lines or warehouse automation.

Collaborative Robots

Collaborative robots, or cobots, work safely alongside humans in shared workspaces. Unlike traditional robots that operate in isolated environments, cobots use AI-powered perception, ML, and real-time decision-making to adapt to dynamic human interactions.

- AI-driven computer vision helps cobots detect human movements, recognize objects, and adjust their actions accordingly.

- ML algorithms enable them to improve task execution over time by learning from human inputs and environmental feedback.

- NLP and gesture recognition allow cobots to understand commands and collaborate more intuitively with human workers.

Universal Robots' UR Series is a good example of a cobot used in manufacturing. These cobots help with tasks like assembly, packaging, and quality inspection. They work alongside factory workers to improve efficiency and human-robot collaboration.

AI-Powered Humanoid Robots

AI-based humanoid robots replicate the human form, cognitive abilities, and behaviors. They integrate AI to perform completely autonomous tasks or collaborate with humans.

These robotic systems combine mechanical structures with AI technologies like CV and NLP to interact with humans and provide assistance.

For example, Sophia is one of the most well-known AI-powered humanoid robots, developed by Hanson Robotics. Sophia engages with humans using advanced AI, facial recognition, and NLP. She can hold conversations, express emotions, and even learn from interactions.

AI Models Powering Robotics Development

AI is transforming the robotics industry, allowing organizations to build large-scale autonomous systems to handle complex tasks more independently and efficiently.

Key advancements driving such transformation include DL models for perception, reinforcement learning (RL) frameworks for adaptability, motion planning for control, and multimodal architectures for processing different types of information.

Let’s discuss these in more detail:

Deep Learning for Perception

DL processes images, text, speech, or time-series data from robotic sensors to analyze complex information and identify patterns. DL algorithms, like convolutional neural networks (CNNs), can analyze image and video data to understand its content. In contrast, Transformer and recurrent neural network (RNN) models process sequential data like speech and text.

A sample CNN architecture for image recognition

For instance, AI-based CV models play a crucial role in robotic perception, enabling real-time object recognition, tracking, and scene understanding. Some commonly used models include:

- YOLO (You Only Look Once): A fast object detection model family that enables real-time localization and classification of multiple objects in a scene, making it ideal for robotic navigation and manipulation.

- SLAM (Simultaneous Localization and Mapping): A framework combining sensor data with AI-driven mapping techniques to help robots navigate unknown environments by building spatial maps while tracking their position.

- Semantic Segmentation Models: Assign class labels to every image pixel, enabling a robot to understand scene structure for tasks like autonomous driving and warehouse automation. Common examples include DeepLab and U-Net.

- DeepSort for Object Tracking: A tracking-by-detection model that tracks objects in real time by first detecting them and assigning a unique ID to each object.

Reinforcement Learning for Adaptive Behavior

RL enables robots to learn through trial and error by interacting with their environment. The robot receives feedback in the form of rewards for successful actions and penalties for undesirable outcomes. Popular RL frameworks used in robotics include:

- Deep Q-Network (DQN): DQN uses DL to learn the Q-function. The technique allows agents to store their experiences in batches and use samples to train the neural network.

- Lifelong Federated Reinforcement Learning (LFRL): This architecture allows robots to continuously learn and adapt by sharing knowledge across a cloud-based system, enhancing navigation and task execution in dynamic environments.

- Q-learning: A model-free reinforcement learning algorithm that helps agents learn optimal policies through trial and error by updating Q-values based on rewards received from the environment.

- PPO (Proximal Policy Optimization): A reinforcement learning algorithm that balances exploration and exploitation by optimizing policies using a clipped objective function, ensuring stable and efficient learning.

Multi-modal Models

Multi-modal models combine data from sensors like cameras, LiDAR, microphones, and tactile sensors to enhance perception and decision-making. Integrating multiple sources of information helps robots develop a more comprehensive understanding of their environment. Examples of multimodal frameworks used in robotics include:

- Contrastive Language-Image Pretraining (CLIP): Helps robots understand visual and textual data together, enabling tasks like object recognition and natural language interaction.

- ImageBind: Aligns multiple modalities, including images, text, audio, and depth, allowing robots to perceive and reason about their surroundings holistically.

- Flamingo: A vision-language model that processes sequences of images and text, improving robotic perception in dynamic environments and enhancing human-robot communication.

Challenges of Integrating AI in Robotics

Advancements in AI are allowing robots to perceive their surroundings better, make real-time decisions, and interact with humans. However, integrating AI into robotic systems presents several challenges. Let’s briefly discuss each of them.

- Lack of Domain-specific Data: AI algorithms require a large amount of good quality data for training. However, acquiring domain-specific data is particularly challenging in specialized environments with unique constraints. For instance, data collection for surgical robots requires accessing diverse real-world medical data, which is difficult due to ethical concerns.

- Processing Diverse Data Formats: A robotic system often depends on various sensors that generate heterogeneous data types such as images, signals, video, audio, text, and other modalities. Combining these sensors' information into a cohesive AI system is complex. It requires advanced sensor fusion and processing techniques for accurate prediction and decision-making.

- Data Annotation Complexity: High-quality multimodal datasets require precise labeling across different data types (images, LiDAR, audio). Manual annotation is time-consuming and expensive, while automated methods often struggle with accuracy.

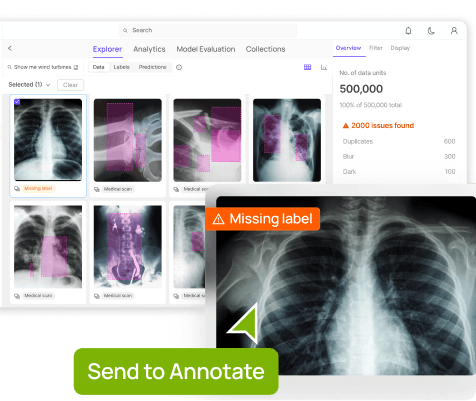

How Encord Ensures High-Quality Data for Training AI Algorithms for Robotics Applications

The discussion above highlights that developing reliable robotic systems requires extensive AI training to ensure optimal performance. However, effective AI training relies on high-quality data tailored to specific robotic applications.

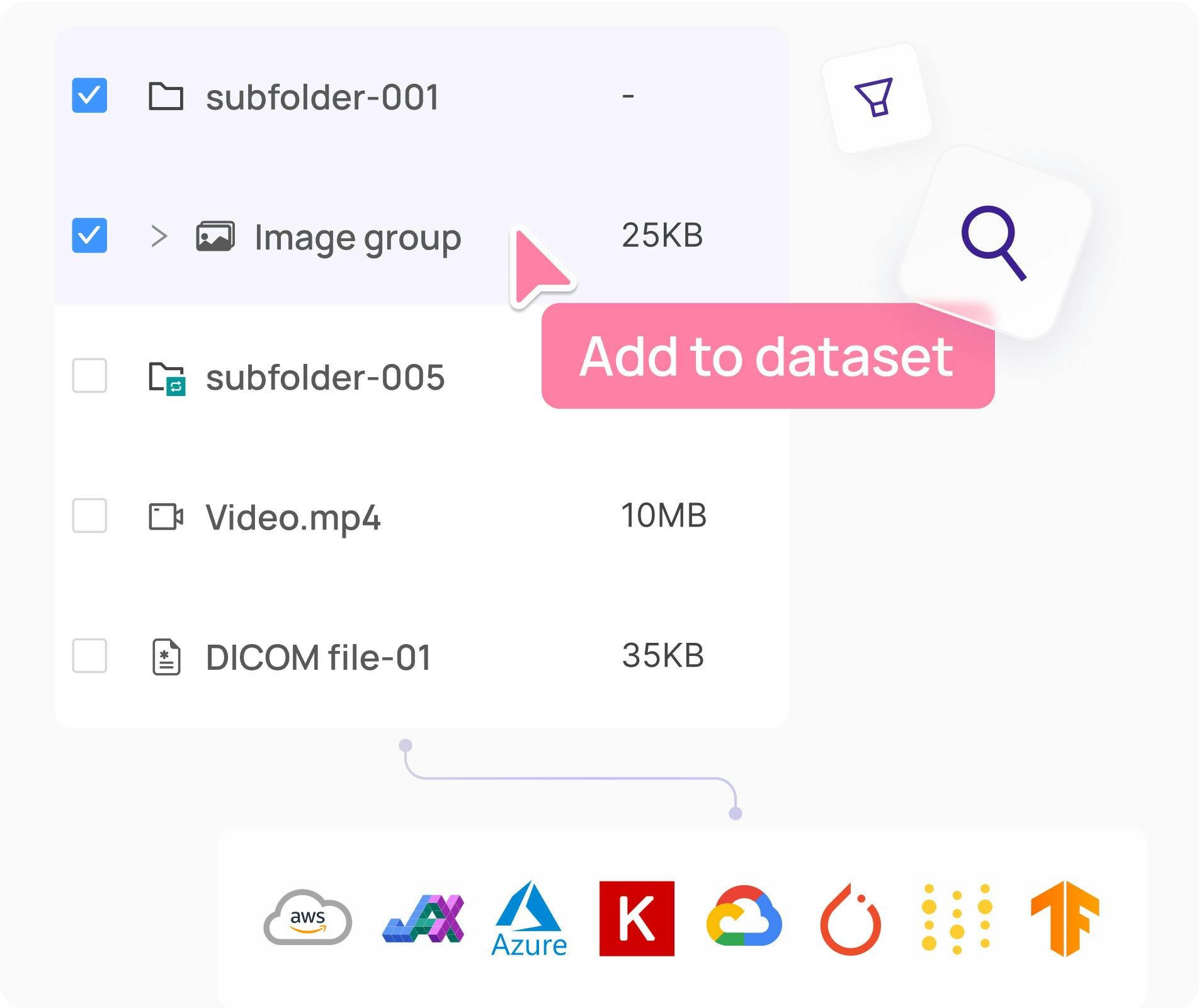

Managing the vast volume and variety of data presents a significant challenge, necessitating the use of end-to-end data curation tools like Encord to streamline data annotation, organization, and quality control for more efficient AI model development for robotics.

Encord is a leading data development platform for AI teams that offers solutions to tackle issues in robotics development. It enables developers to create smarter, more capable robot models by streamlining data annotation, curation, and visualization. Below are some of Encord’s key features that you can use to develop scalable robotic frameworks.

Encord Active for data cleaning

Intelligent Data Curation for Enhanced Data Quality

The Encord index offers robust AI-assisted features to assess data quality. It uses semi-supervised learning algorithms to detect anomalies, such as blurry images from robotic cameras or misaligned sensor readings. It can detect mislabeled objects or actions and rank labels by error probability. The approach reduces manual review time significantly.

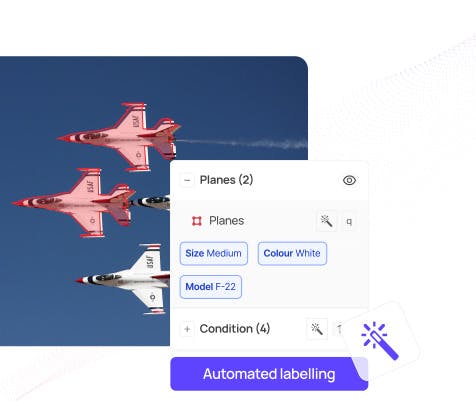

Precision Annotation with AI-Assisted Labeling for Complex Robotic Scenarios

Human annotators often struggle to label the complex data required for robotic systems. Encord addresses this through advanced annotation tools and AI-assisted features. It combines human precision with AI-assisted labeling to detect and classify objects 10 times faster.

- Custom Ontologies: Encord allows robotics teams to define custom ontologies to standardize labels specific to their robotic application. For example, defining specific classes for different types of obstacles and robotic arm poses.

- Built-in SAM 2 and GPT-4o Integration: Encord integrates state-of-the-art AI models to supercharge annotation workflows like SAM (Segment Anything Model) for fast auto-segmentation of objects and GPT-4o for generating descriptive metadata. These integrations enable rapid annotation of fields, objects, or complex scenarios with minimal manual effort.

- Multimodal Annotation Capabilities: Encord supports audio annotations for voice models used in robots that interact with humans through voice. Encord’s audio annotation tools use foundational models like OpenAI’s Whisper and Google’s AudioLM to label speech commands, environmental sounds, and other auditory inputs. This is important for customer service robots and assistive devices requiring precise voice recognition.

Future of Robotics & AI

AI and robotics together are driving transformative changes across various industries. Here are some key areas where these technologies are making a significant impact:

Edge and Cloud Computing

Edge computing offers real-time data processing within robotic hardware, which is important for low-latency use cases such as autonomous navigation. Cloud computing provides vast data storage and powerful processors to process large amounts of data for AI model training. This allows robots to react quickly to their immediate surroundings and learn from large data sets.

Smart Factories

AI-powered robots are transforming factories, which use automation, IoT, and AI-driven decision-making to optimize manufacturing, streamline workflows, and enhance the supply chain.

Unlike traditional factories that rely on fixed processes and human efforts, smart factories use interconnected machines, sensors, and real-time analytics to adapt to production needs dynamically. These systems enable predictive maintenance, optimization, and autonomous quality control.

For example, Ocado’s robotic warehouse uses swarm intelligence to coordinate thousands of small robots for high-speed order fulfillment.

Swarm Robotics

Swarm robotics uses a group of robots to solve a complex task collaboratively. AI makes these swarms coordinate their movements, adapt to changing environments, and perform tasks like search and rescue, environmental monitoring, and agricultural automation.

SwarmFarm Robotics spraying pesticides

For example, SwarmFarm Robotics in Australia uses autonomous robots in precision agriculture. These robots work together to monitor crop health, spray pesticides, and plant seeds. Coordinating their actions allows them to cover large areas quickly and adapt to different field conditions.

Space and Planetary Exploration

AI-powered robots play a crucial role in space exploration by navigating unknown terrains, conducting scientific experiments, and performing maintenance in harsh environments. AI enables these robots to make autonomous decisions in real time, which reduces their reliance on direct communication with Earth and overcomes delays caused by vast distances.

For example, NASA’s Perseverance rover on Mars features AI-driven systems that enable it to navigate the Martian surface autonomously. The rover uses AI to identify and avoid obstacles, choose its paths, and select expected locations for scientific analysis. This autonomy is crucial for exploring areas where real-time communication is not feasible.

AI in Robotics: Key Takeaways

AI is transforming robotics by enabling machines to perceive, learn, and make intelligent decisions. This transformation is driving advancements across industries, from manufacturing to healthcare. Below are the key takeaways on how AI is shaping robotic automation.

- AI Transforms Robotics: AI enhances robotic capabilities by improving decision-making, perception, and adaptability, making robots more autonomous and efficient.

- Challenges of Incorporating AI in Robotics: Integrating AI in robotics comes with challenges such as acquiring domain-specific data, processing diverse sensor inputs, ensuring AI explainability, achieving scalability across environments, and maintaining seamless hardware integration for optimal performance.

Encord for Robotics: Encord provides AI-powered tools for high-quality data annotation and management, enhancing AI model training for robotics.

Explore the platform

Data infrastructure for multimodal AI

Explore product

Explore our products

AI enables robots to perceive, learn, and make decisions, improving automation in industries like manufacturing, healthcare, and self-driving cars.

AI enhances robot autonomy, adaptability, and intelligence, allowing them to operate efficiently in dynamic environments.

Robotics involves building physical machines, while AI provides intelligence for learning, decision-making, and adaptability.

Machine learning in robotics enables robots to learn from data, adapt to new situations, and improve their performance over time. It is used for tasks like object recognition, motion planning, and autonomous decision-making.

AI-powered robots will drive automation, smart factories, swarm robotics, and space exploration, transforming industries and daily life.

Yes, Encord collaborates with companies involved in autonomous driving, providing tools for image and video annotation that are essential for training AI models in this sector. Our platform is designed to meet the unique demands of smart city and autonomous vehicle applications.

Encord is designed to accommodate the specialized labeling requirements often found in robotics projects. The platform's flexibility allows for customization and adaptation to unique use cases, making it a suitable choice for teams working on advanced robotics applications.

Encord has extensive experience collaborating with robotics customers, focusing on three key areas: providing labeling tools for training data, supporting data indexing and curation, and implementing human-in-the-loop solutions to enhance model accuracy and reliability.

Encord's platform is designed to streamline the training of models using data collected from robotics systems. It supports data flow through pipelines, enabling teams to focus on refining their models based on real-time data and insights generated during operations.

Yes, Encord's platform is designed to integrate seamlessly with existing robotic systems. This compatibility enables teams to enhance their current workflows and improve the functionality of their robotics solutions through advanced AI training and data management.

Encord supports robotics teams by offering a platform where they can easily integrate hosted AI components and middleware. This allows teams to achieve quick wins through AI engineering, streamlining their development processes and enhancing overall functionality.

Encord plays a vital role in the machine learning pipeline for robotics by providing tools for data management, annotation, and model evaluation. This ensures that robotic systems can be trained effectively to handle complex tasks in dynamic environments.

Encord offers a comprehensive platform that helps AI and robotics teams streamline their annotation processes. Our tools facilitate efficient data management, enabling teams to focus on developing and refining their machine learning models.

Encord enhances collaboration by allowing users to define ontologies and align annotation standards with automotive OEMs. This ensures that AI models can communicate effectively using the same terminology and classifications as designers.