Contents

What is Personal Protective Equipment (PPE)?

Issues in PPE Compliance

Role of Computer Vision in PPE Detection

Implementation of PPE Detection Systems

Case Study

Benefits of CV in PPE Detection

Implementation Challenges

PPE Detection Using Computer Vision: Key Takeaways

Encord Blog

PPE Detection Using Computer Vision for Workplace Safety

5 min read

Employees frequently become victims of fatal occupational accidents due to poor safety standards or protocols. Recent statistics reveal that around 340 million workplace accidents occur annually. The injuries result in severe consequences for the worker and their family while causing significant productivity losses for the company.

One strategy to mitigate these incidents is implementing a strict policy of wearing personal protective equipment (PPE) when working in hazardous environments. This equipment can include protective glasses, high-visibility vests, gloves, and helmets to ensure the workers remain safe and productive in the long run.

However, manually monitoring PPE compliance is challenging as it involves the daily supervision of an extensive workforce. An alternative is using the latest computer vision (CV)-based solutions and frameworks to determine whether workers wear PPE according to safety protocols.

In this article, we will discuss the significance of PPE, compliance issues, the role and benefits of using CV to detect PPE for workplace safety, and a few implementation challenges.

What is Personal Protective Equipment (PPE)?

Organizations require on-site staff working on the factory floor or on construction sites to wear personal protective equipment (PPE) to enhance workplace safety. Multiple types of PPE include helmets, gloves, safety vests, hard hats, safety glasses, face shields, and respirators.

Protective gear ensures safe work environments in places where the chances of injuries or illness are high. Proper PPE usage also increases worker productivity in the long term, as workers can perform sensitive tasks safely without fear of accidents.

In addition, companies can avoid costs and downtime associated with non-compliance by requiring workers to wear safety gear as part of national and international safety regulations.

Issues in PPE Compliance

Although complying with PPE standards offers significant benefits, organizations face multiple challenges in ensuring workers follow the stated PPE rules.

The following list highlights three major issues in PPE compliance:

Human Error and Oversight

Workers may forget to wear PPE or deliberately neglect safety protocols due to discomfort. With different PPE items serving different purposes, workers may get confused as they may not know which equipment to use for which task type. This is likely to occur in workplaces with inadequate training on PPE equipment use.

Manual Monitoring Limitations

Monitoring workers manually to determine whether they use PPE is expensive and error-prone. Organizations must hire and train supervisors who can miss non-compliance instances in large and complex environments.

Impact of Non-compliance on Safety and Costs

Non-compliance can cause higher injury rates, worker absences, and turnover. Workers’ deteriorating health can also increase operational costs involving medical expenses, legal liabilities, and penalties.

Role of Computer Vision in PPE Detection

Advancements in artificial intelligence (AI) algorithms allow organizations to quickly implement cutting-edge computer vision technology to automate personal protective equipment detection.

Let’s understand how computer vision helps build an efficient PPE detection system.

What is Computer Vision?

Computer vision techniques allow machines to process and analyze visual datasets such as images and videos, to extract relevant data patterns. It uses AI algorithms to perform multiple tasks, such as image classification, object detection, and segmentation.

Organizations in several domains use CV to automate workflows and minimize operational costs. For instance, computer vision algorithms help diagnose medical images in healthcare, detect product anomalies in manufacturing, identify objects on the road for self-driving cars, and optimize inventory management in warehouses.

How Computer Vision Enhances PPE?

Since CV allows users to analyze visual data, it can improve PPE detection by mitigating the challenges discussed earlier.

Here are a few ways CV achieves this:

- Real-time Monitoring and Detection: CV systems can automatically detect PPE in real-time and ensure workers use it according to safety requirements.

- Reduction of Human Error: With advanced model training, CV frameworks can work autonomously, reducing the risk of human error and quickly identifying non-complying behavior.

- Automation of Compliance Checks: CV-based detection can reduce administrative burdens by quickly generating alerts in case of PPE violations and streamlining enforcement workflows. It can send periodic reports and notifications to relevant authorities with relevant data on PPE usage.

Technical Components of PPE Detection Systems

Before implementing a PPE detection system, organizations must invest in relevant hardware and software components to allow the system to function efficiently.

Below are the key requirements for implementing a PPE detection mechanism.

Hardware Requirements

While precise hardware requirements vary according to the system deployed, critical elements include cameras, sensors, and edge computing devices.

- Cameras and Sensors: CV systems require high-resolution cameras and sensors to capture images and video feeds from multiple angles and locations. They must also be robust to environmental disturbances and perform in harsh conditions, such as withstand high or low temperatures in factory sites. This is where PoE cameras often excel. They typically deliver superior performance with high-resolution video, reliable operation, and the ability to thrive in challenging conditions, making them a suitable choice for many CV system implementations.

- Edge Computing Devices: While cameras and sensors capture relevant data, edge computing devices help process, analyze, and transfer data to enterprise platforms.

The devices include small but powerful single-board computing units like NVIDIA’s Jetson or Raspberry Pi.

Users can integrate these modules into cameras and sensors for on-site real-time accelerated computations.

Software Requirements

CV systems require advanced deep learning algorithms that can process images with the latest techniques for accurate predictions. Organizations must also invest in platforms that help them smoothly integrate their existing infrastructure with CV frameworks.

- Deep Learning Models: PPE systems need object detection models such as You Only Look Once (YOLO) or Faster Region-based Convolutional Neural Network (Faster-RCNN) to recognize PPE gear.

- Image Processing Techniques: The techniques include pipelines that process raw data for use by detection models. Data processing steps may include transformation, normalization, and augmentation.

- Integration with AI and Machine Learning Frameworks: An efficient detection system requires integrating CV models with machine learning platforms such as TensorFlow, PyTorch, and OpenCV to streamline the development, validation, and deployment process.

Implementation of PPE Detection Systems

The next step, once you meet the necessary hardware and software requirements, is implementing a PPE detection system.

Although implementation can be complex, it usually requires three steps: data collection and annotation, model training and validation, deployment, integration, and continuous operations.

Data Collection and Annotation

Efficient model training requires users to collect and curate extensive datasets with accurate annotations. Below are a few guidelines to help companies quickly collect and annotate data.

Data Collection

Organizations must train object detection models on diverse datasets with multiple PPE types. This process ensures that the algorithm recognizes all the varieties of PPE to detect non-compliance accurately.

The dataset must also include images and videos with different lighting conditions, backgrounds, angles, locations, and other obstacles. The method will ensure the model recognizes PPE gear in complex and dynamic environments.

Users can collect such data using cameras, sensors, and public image repositories. Using generative AI algorithms, they can also generate synthetic data that resembles real images.

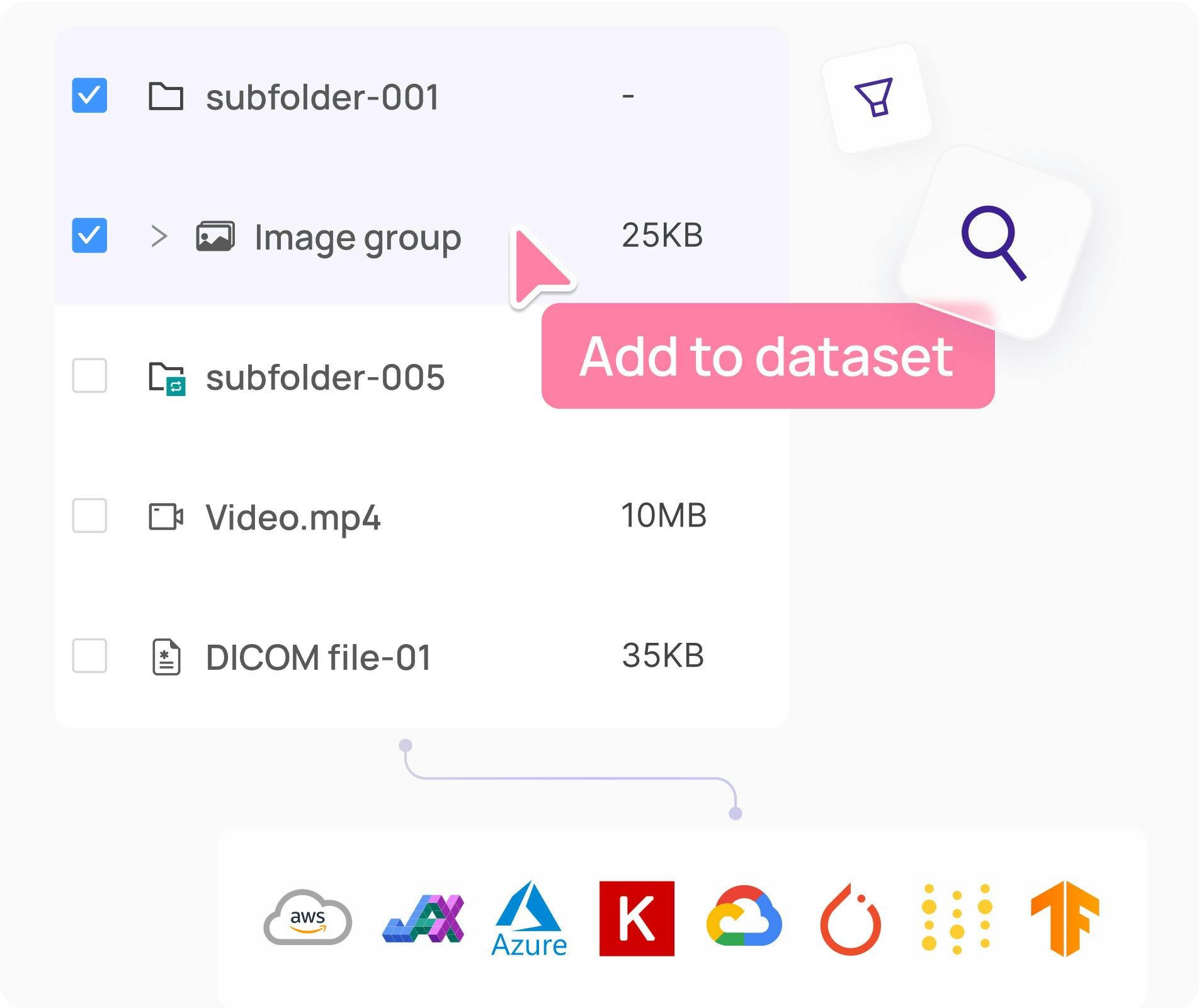

They can use tools such as Encord Index, which helps register, curate, and manage multiple data types, including metadata. With Index, you can import data from cloud sources or local storage. You can also search, sort, and filter your datasets to:

- Identify patterns, trends, or anomalies within a subset of the data.

- Detect duplicates, outliers, and data inconsistencies.

- Remove irrelevant, noisy, and erroneous data.

After filtering, sorting, and searching your data, use Collections with Annotate Projects to streamline your annotation process or send your dataset downstream for processing and training/fine-tuning models.

For instance, you can filter data according to the amount of blur in images. The filtered dataset will contain blurred images that are unsuitable for model training. You can extract this data subset and process it further to remove blurs and other inconsistencies.

Data Annotation

The next step is data annotation. Annotation involves labeling images and video clips to describe their content. Accurate annotation will help the model recognize which PPE is present in an image or video.

Although users can perform annotation manually, this method is tedious and error-prone. A better alternative is to use annotation platforms that contain relevant features and methods to help automate the annotation process.

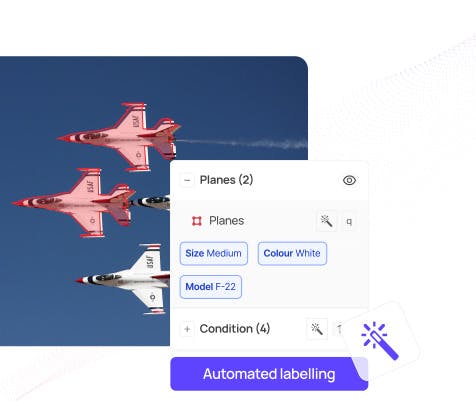

For instance, Encord Annotate is an AI-assissted annotation platform that lets you label images and videos using customizable workflows and collaborative features. It supports all the latest annotation methods, including bounding boxes, polygons, polylines, key points, and segmentation.

Encord Annotate also includes micro-models and automated labeling features to customize annotations to your specific datasets and use cases. Users can train micro-models on relevant datasets and use them to label images across different projects.

Automated labeling includes segment anything model (SAM), interpolation, and object tracking methods to speed up annotation by filling in missing labels using information from manual annotations.

Data Curation

Once the annotation is complete, developers must curate data by organizing the data assets into relevant categories, filtering outliers, and fixing anomalies such as blurred or unclear images.

Curation may also involve data anonymization to ensure compliance with privacy regulations. Creating metadata is also helpful, as it can allow new developers and annotators to understand the context and purpose of data items quickly.

Data Pre-processing

The next is data pre-processing, which may involve image resizing, normalization, noise reduction, and determining the optimal train-test split for model training and validation.

Data pre-processing helps in creating a clean dataset that models can readily use to extract meaningful data patterns. Automated pipelines can speed up the process and reduce errors.

Feature Engineering

After obtaining a clean dataset, the next step is to extract relevant features from the image data to improve model performance and reduce computational complexity.

The process involves identifying unique textures that distinguish PPE equipment, analyzing color distributions, assigning key points to help the model recognize corners and edges, and highlighting different backgrounds and environmental conditions.

Model Training and Validation

After processing data, the next stage is training and validating a model. Training involves a model learning data patterns to generate accurate predictions, while validation tests model performance on unseen data.

Model Training

Training involves techniques that feed annotated data into a model to help it learn underlying data patterns for predicting outcomes.

In the context of PPE detection, the model will learn to recognize different PPE and predict accurate labels for images containing a particular PPE type.

The process requires extensive computing power and expertise to train a model on a large dataset with correct hyperparameters.

Modern methods involve fine-tuning foundation models such as YOLO-World, GroundingDINO, Single Shot MultiBox Detector (SSD), and Detection Transformer (DETR) to perform domain-specific detection tasks for better performance.

These pre-trained models possess extensive knowledge regarding multiple items, giving them superior generalization ability on new datasets. Experts can repurpose these models for PPE detection use cases, allowing them to reduce training time and cost.

Model Validation

While training ensures the model accurately predicts image labels from known data, validation checks if the model performs equally well on a new dataset.

It involves computing multiple metrics, such as accuracy, precision, recall, and F1-score, to determine whether model predictions are reliable.

Although you can compute these metrics manually using custom pipelines, a more systematic approach is to use a platform that automatically computes multiple metrics to assess performance.

The approach ensures quick, consistent, and accurate calculations while offering more comprehensive insights into model performance.

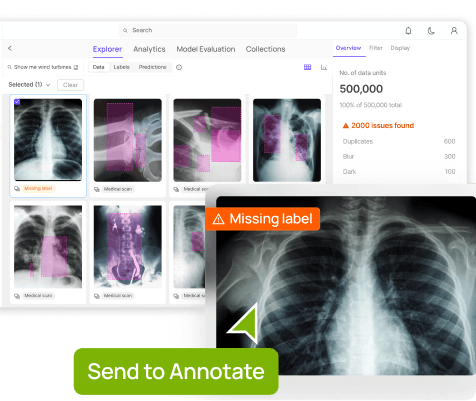

Encord Active evaluates model performance based on relevant metrics and offers insightful visualizations to help understand how well the model can detect PPE when deployed on sensors or devices in the workplace.

Encord Active features metrics to measure label, data, video, and model quality. These features help you analyze the problem and debug model quality issues in cases of poor model performance.

Deployment and Integration

The next stage is deploying the trained models in production and integrating them with safety management systems to track compliance.

Deploying Models on Edge and Non-Edge Devices

Organizations can deploy models on edge devices for on-site real-time processing. For instance, cameras integrated with NVIDIA Jetson chips can detect PPE use locally and send usage statistics to relevant authorities.

The method improves prediction accuracy and speed through parallel processing. Organizations can also integrate these devices with cloud storage solutions for enhanced security and scalability.

Alternatively, companies can use on-premises central servers to process data coming from camera feeds in real-time. Such systems offer more computational power than edge devices and allow for more scalability.

Also, multiple models can share the server resources, making it more cost-effective. Additionally, a central team can manage upgrades and maintenance routines more efficiently.

Overall, the choice of edge or non-edge infrastructure depends on specific use-case. Edge solutions are more effective in cases where privacy is a significant concern and limited finance makes it challenging to invest in extensive on-site infrastructure.

Conversely, non-edge solutions (e.g., Cloud platforms) are helpful in cases where the system requires high computational power and latency is not an issue.

Integration with Existing Safety Management Systems

Integrating these solutions with a safety management platform is necessary for an end-to-end compliance monitoring system.

For instance, the organization can define usage thresholds and use automated pipelines that compare actual usage with pre-defined targets.

The system can automatically generate alerts that notify management where and when non-compliance occurs.

Continuous Operations

The last stage, after deployment and integration, concerns continuous operations. The phase involves monitoring performance and implementing regular upgrades to ensure the system’s accuracy and reliability.

A few ways to keep the detection system up-to-date and working according to expectations include regular model training on new datasets, installing device software updates, establishing real-time alerts to quickly identify issues, and monitoring key performance indicators (KPIs) against targets to track compliance.

Case Study

Let’s see how a company can implement an end-to-end detection system to overcome safety and compliance challenges.

The Problem

A construction company wants to build a PPE detection system to monitor PPE compliance but faces some of the challenges below.

- Construction sites have dynamic illumination levels, shadows, multiple activities, and several PPE types with different colors and designs. These factors make implementing a PPE detection system challenging.

- Dynamic illumination levels, for instance, affect the visibility of PPE items at different sites during the day, and shadows from other objects, such as construction equipment, can obscure the primary PPE gear.

- Similarly, the multitude of activities on construction sites makes it difficult for a PPE detection system to analyze and detect all movements, and the variety of PPE items hinders the detection model’s ability to identify a particular PPE item accurately.

The challenges call for a robust detection system that can generalize well to new objects and accurately detect occluded items in crowded environments.

The steps below demonstrate how the company can successfully deploy such a detection framework using state-of-the-art equipment and an object detection model.

1. Data Collection and Annotation

The company can use customized 2D cameras instead of using an off-the-shelf device to ensure the hardware is suitable for dynamic construction sites.

Each camera can include a power, processing, and data storage unit. Since construction sites often have dust, sunlight, rain, and heavy equipment, the company can cover the devices with plastic boxes and place them on top of tripods to ensure the cameras capture a wide angle from different locations.

The cameras can record 41-second video clips and send the data to a cloud browser. It can use solar power to run the devices, since finding an uninterrupted electrical supply on a construction site is challenging.

Finally, the company can use automated data curation and labeling tools to curate and annotate images extracted from video clips.

Encord Index natively integrates with Encord Annotate to help developers annotate the curated data using automated features to speed up the labeling process. They can also use the latest labeling methods to manually mark key points and draw bounding boxes around PPE equipment.

Additionally, Encord’s support for video annotation can streamline annotation more effectively, as developers can directly label relevant objects in video clips for more accurate results.

2. Data Pre-processing and Feature Engineering

After annotation, developers can apply relevant data transformation using automated pipelines. The transformations can include image resizing, normalization, and augmentation.

Also, they must extract features that differentiate one PPE equipment from the other. Such features may include the equipment’s shape, size, edges, corners, and colors.

Lastly, it must determine an appropriate train-test split to train, test, and validate the model. The size of the data will help decide a suitable split.

3. Model Training and Validation

The next stage is selecting a suitable model to train and validate. A cost-effective approach is to fine-tune a visual foundation model (VFM) using the data extracted in the previous stage.

Once trained, developers can validate the model using relevant metrics, such as identification and recall rates. Encord Active automatically computes multiple metrics to measure performance with intuitive visualizations.

4. Model Deployment and Integration

The company can use multiple frameworks to build, train, and deploy the model. Popular open-source frameworks include TensorFlow, PyTorch, and Scikit-Learn.

Additionally, it can integrate the system with a safety management framework to send real-time PPE compliance data to notify and alert authorities in case of anomalies.

5. Continuous Operations

Lastly, the company can build real-time alert mechanisms that can quickly identify issues and establish KPIs with achievable targets to measure ongoing performance.

Benefits of CV in PPE Detection

As the above case study highlights, using CV for PPE detection offers multiple benefits over a manual system. Below are a few key benefits of CV-based PPE detection.

- Efficiency: A CV-based system captures non-compliance instances more efficiently through real-time monitoring and instant alerts regarding non-complying behavior.

- Scalability: Organizations can install multiple edge devices to cover many locations and detect PPE compliance. The method allows for monitoring all the employees simultaneously.

- Data Analytics: CV systems can process and analyze extensive data to help managers track PPE usage statistics. The analysis may reveal actionable insights regarding safety trends and employee pain points.

- Remote Support: Safety officers can monitor multiple sites from a central location and provide instant support to remote locations.

Implementation Challenges

Although using CV for PPE detection offers numerous advantages, it is challenging to implement in complex and dynamic environments.

The list below highlights a few hurdles and mitigation strategies that organizations may follow during implementation.

Technical Challenges

The most significant issue is PPE variety, as the PPE detection model must recognize multiple PPE types with varying colors, designs, and shapes. Collecting, storing, and processing a diverse dataset that includes all variations in dynamic environments is challenging.

Organizations can address the problem by adopting data augmentation techniques to diversify the dataset. They can also experiment with data generation methods to create synthetic data for better model training.

Lastly, they can strategically place cameras in different locations with occlusion and poor lighting conditions to help the model recognize patterns in low-visibility areas.

Privacy and Ethical Considerations

Real-time PPE detection requires constant monitoring of employees through cameras. The method may result in workers feeling uneasy and having privacy concerns. With rising privacy regulations, implementing visual detection systems becomes more challenging as organizations must ensure they are complying with international standards.

Companies can establish strict data privacy guidelines and obtain employee consent before monitoring workers. They can also use anonymization techniques to build training datasets.

Scalability and Maintenance

Scaling and maintaining PPE detection systems across different environments can be challenging. The issue requires tailored solutions that suit specific locations, evolving safety rules, new PPE types, and changing conditions as the business expands.

Businesses can mitigate these concerns by scheduling regular updates and using automated tools to streamline model training with new data. They must also implement systems with modularity to ensure quick upgrades and use APIs to integrate seamlessly with new safety management systems.

PPE Detection Using Computer Vision: Key Takeaways

Computer vision (CV) offers a more scalable and cost-effective way for PPE detection to ensure workplace safety.

Below are a few critical points regarding CV-based PPE detection systems.

- Technical Components of CV-based PPE Detection System: PPE detection systems require suitable hardware and software components. Appropriate hardware includes cameras, sensors, and edge-computing devices. Software elements include a scalable CV model, image processing pipelines, and solutions for integrating AI systems with deployment platforms.

- Implementation Steps: The process begins with collecting and annotating diverse data. The next step is model training and validation, with model deployment and integration with the safety management system being the last step.

- Implementation Tools: Organizations can streamline the implementation process through AI solutions that help with data collection, annotation, and model validation.

Encord is an end-to-end data development platform that helps you curate and annotate large datasets. It also supports model validation through an extensive range of data and model quality metrics and AI-assisted model debugging features.

So, sign up for Encord now to optimize PPE detection and improve workplace safety.

Explore the platform

Data infrastructure for multimodal AI

Explore product

Explore our products

Personal Protective Equipment (PPE) is the safety gear that workers use to avoid workplace accidents. It includes vests, goggles, hard hats, helmets, and respirators.

Computer vision (CV) uses deep learning models to detect PPE equipment automatically to ensure PPE compliance.

CV-based PPE detection helps with real-time monitoring and reduces human error by simultaneously detecting PPE compliance in multiple locations.

CV models can detect helmets, vests, goggles, face masks, ear protection, and gloves.

Challenges of implementing computer vision to detect PPE include technical issues associated with low-visibility areas and dynamic environments, privacy concerns, and maintenance costs.